The project serves as a strong example of the complex, bespoke engineering challenges our team here at Bowers Electricals is equipped to solve, from early-stage design through to full system testing and validation.

The core challenge of the project stemmed from a fundamental difference between the end user’s operational requirements and the UK’s standard electrical infrastructure. While the UK’s grid operates at a 50 Hz power supply, the end user required equipment capable of operating at a 60 Hz cycle.

Rather than adopting a traditional generator-based approach, which can introduce noise, emissions, and operational inefficiencies, Metartec specified a solution based on static frequency converters. This approach offered a cleaner, quieter, and more efficient method of frequency conversion, while also providing greater long-term reliability and controllability.

However, this solution placed very specific and demanding requirements on the supporting transformer design, particularly in terms of electrical behaviour, harmonics, inductance, and overall system stability.

To enable the frequency conversion system, Bowers Electricals designed four fully bespoke transformers, each engineered specifically for this application. The solution included two 4000 kVA transformers to supply power to the static frequency converters, along with two 3500 kVA isolation transformers installed downstream of the converters. These isolating transformers played a critical role in ensuring the safe, stable, and reliable operation of the overall system.

Due to the converters’ precise electrical requirements, Bowers’ design team developed a tailored solution incorporating a gapped core design. This allowed accurate control of inductance, inrush current, and overall RLC performance, all of which were essential to achieving stable interaction between the transformers and the frequency conversion equipment.

A key milestone of the project was the comprehensive Factory Acceptance Testing (FAT), which was carried out at Bowers Electricals’ factory. To support this, Metartec transported its complete system to the Bowers site, including a 3 MW N+1 Static Frequency Converter. This system was made up of 6 x 600 kW UPS-CUM-Frequency converter transformers configured specifically to convert 50 Hz input power to a 60 Hz output.

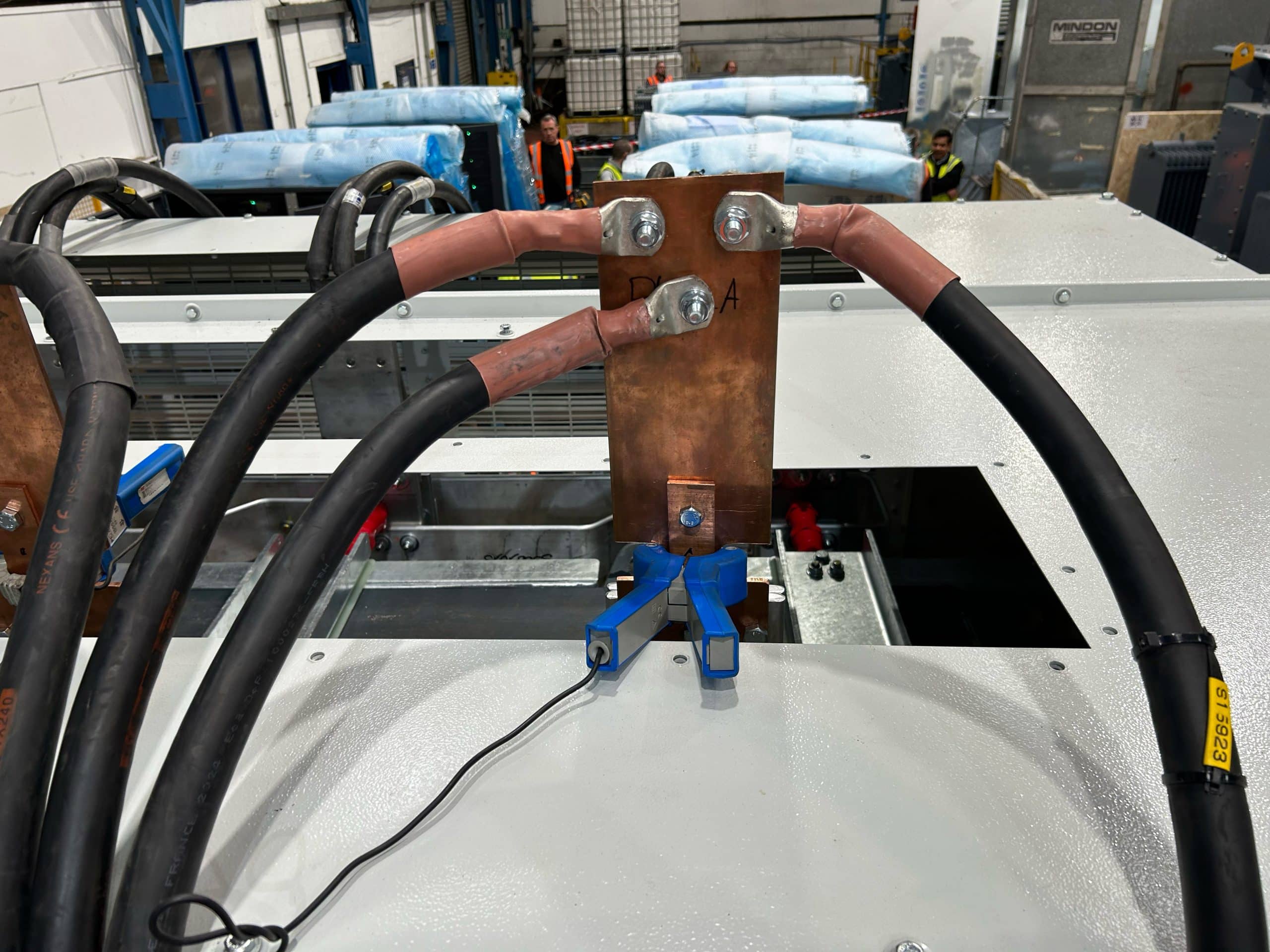

Working closely together, the Bowers Electricals and Metartec teams connected the full system to the 3.5 MVA output transformer. A complete demonstration of the pre-magnetisation process was then conducted under real operating conditions, allowing all parties to observe system behaviour in a controlled but fully representative environment.

The FAT was attended by the customer, consultant, and end user, all of whom witnessed the system perform exactly as designed. From a testing and validation perspective, particular attention was paid to power factor, harmonic performance, and the interaction between the inductive transformers and the capacitive nature of the power electronics.

The project clearly demonstrated the effectiveness of close collaboration between Bowers Electricals and Metartec, as well as the depth of expertise within Bowers Electricals’ engineering and testing teams.

This project stands as a strong example of Bowers Electricals’ capability to deliver high-specification, bespoke transformer solutions for complex power applications. From detailed design and manufacture through to full system integration and testing, the project highlights our ability to support advanced power systems where precision, reliability, and performance are critical.

The project also demonstrated the commitment of our team, who worked beyond standard scope and went the extra mile to support the technical and delivery challenges involved with this highly prestigious project.

We also believe that the story behind the engineering is just as important as the technical outcome. This project, therefore, features in our Behind the Build series. The series brings together our customers and the Bowers engineers on the project, offering an authentic insight into real-world engineering challenges, how they are overcome, and what effective collaboration looks like in practice.

Watch the episode below to hear directly from the team and see what they had to say about delivering this project.