Our tailored programmes ensure your transformers perform safely and reliably, reducing the risk of failure, extending asset life, and helping you meet industry standards. Some insurance providers may require regular transformer maintenance as part of their policy conditions to reduce the risk of failure and ensure compliance with safety standards. Keeping up with service records can also support future claims and demonstrate responsible asset management.

We offer a standard maintenance plan, but can also offer flexible transformer maintenance plans, tailored to suit the demands of your site and equipment. Whether you’re operating a single unit or managing a large-scale installation, our in-house team can build a support programme to keep your assets in optimal condition.

Our typical agreement is based on a five-year contract and consists of intrusive maintenance of all HV equipment and four non-intrusive inspections, including oil sampling of transformers.

We can additionally offer further bespoke options depending on the criticality and usage of your transformer.

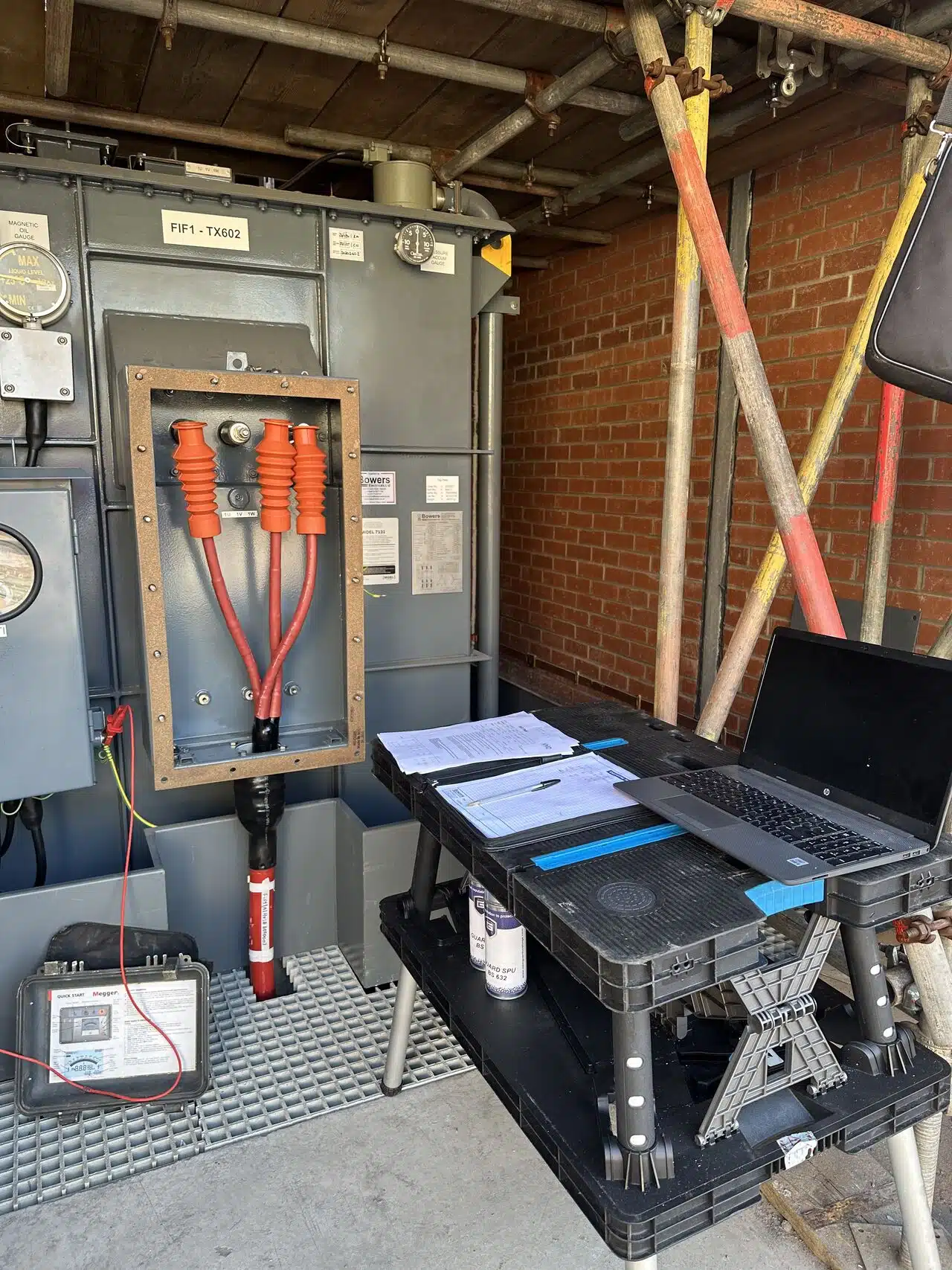

Typical servicing activities include:

Transformer oil sampling and trend analysis are the key indicators to help identify a potential problem with a transformer and can prevent catastrophic failure.

We also offer emergency call-out support and priority response for customers on ongoing service agreements.

A regular maintenance plan offers:

Our team of highly skilled engineers work to the highest industry standards, ensuring every maintenance job is carried out with precision, safety, and long-term performance in mind. With decades of combined experience, we provide comprehensive support for all types and models of transformers

Maintaining accurate servicing records helps meet HSE requirements and ensures that proper steps are being taken to maintain the integrity and safety of your power network. Having complete maintenance records also helps prevent potential prosecution under health and safety regulations.

Some insurance providers may require up-to-date maintenance records as part of their policy conditions to reduce the risk of failure and ensure compliance with safety standards. These records can also support future claims and demonstrate that your equipment is being managed responsibly.

All maintenance is carried out by our fully trained Bowers Electricals engineers. We provide responsive scheduling and on-site servicing across the UK, Scotland and Ireland, including out-of-hours support to minimise any disruption to your operations.

Whether you manage a large industrial facility or a smaller private site, our expert team is here to help keep your power systems safe, reliable, and running efficiently wherever you are.

Our team will work closely with you to design a maintenance plan that fits your equipment, site access, and budget. Whether you need ongoing support or a one-off service, Bowers Electricals is here to keep your transformers running safely and reliably.