In any part of society’s activities, whether in industry, commerce, hospitals, or even homes, the use of electricity is necessary to keep things running. Transformers are a crucial part of the electrical system that converts electrical energy from one voltage to another. Without transformers, the electricity system we have today wouldn’t exist. This blog post highlights the importance of transformer maintenance.

Over time, a transformer can encounter critical issues that lead to failure and can cause problems. Regular maintenance of a transformer aims to maintain both the internal and external parts safely and minimise any transformer downtime. A second but equally important purpose is keeping records about transformer operation, maintenance, and repair history. A well-maintained transformer can operate at peak efficiency, reduce energy waste, and save money on energy bills.

Symptoms of Transformer Problems:

Symptoms of Transformer Problems: The Cost of Delaying Transformer Maintenance:

The Cost of Delaying Transformer Maintenance:Every time maintenance is delayed or cancelled, safety and reliability are impacted. Strategies that focus on cutting costs short-term typically encounter larger long-term expenses, and it is no different for transformer maintenance and their life expectancy.

To avoid legal and financial challenges, such as downtime or injury, companies that own or have transformers on their site must develop and execute effective maintenance plans. Every part of the substations benefits from maintenance, but it is especially important for transformers to be inspected and tested.

Keeping a transformer in top working condition can help prevent running costs from steadily increasing over time and maximising your transformer’s lifetime.

You can view the full maintenance breakdown here.

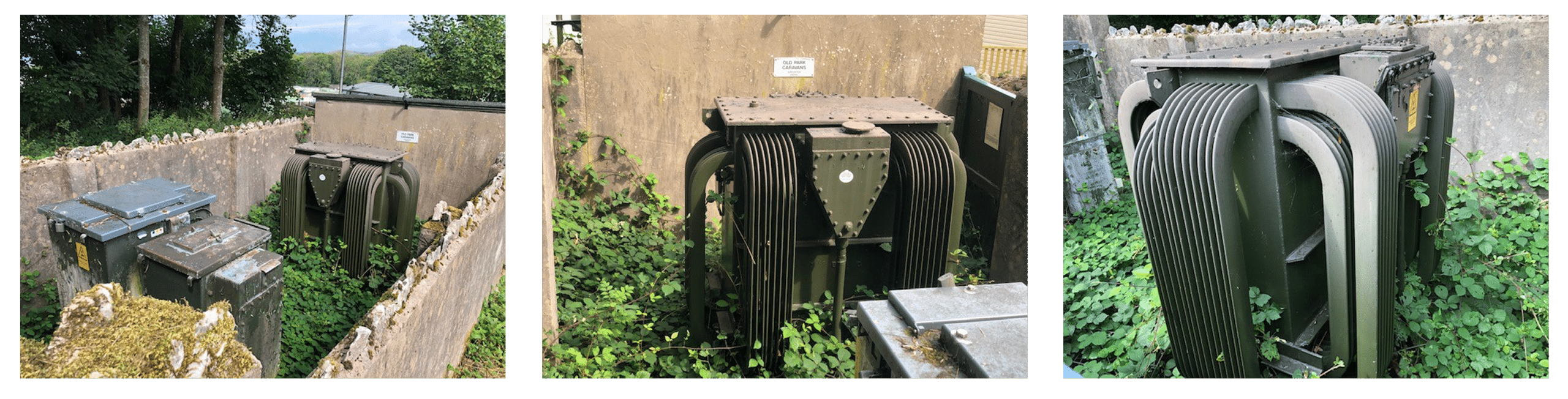

This transformer is a 1500kVA, 11000/433V, Dyn11, KNAN, Distribution Transformer that a customer installed in 2015. Subsequently, they then left the transformer to operate and completely neglected their responsibilities for its ongoing maintenance.

8 years later, the only visible part is a small corner of the HV Switchgear. The transformer had become overgrown with shrubbery and the radiators had been pushed apart with a tree growing between the fins.

Unbelievably, this transformer was still live and still operating the site it was on.

Our site engineer cleared as much as they could and cut the tree at the root to prevent further growth without compromising the radiators and the running of the transformer. New radiators and full removal of the root will require a second more complex visit.

The consequences of this could have been catastrophic for the site, especially if the tree had caused any further damage to the radiators or the tank of the transformer.

Our maintenance team can support you in developing and planning a regular schedule to maintain an efficient transformer. We would always recommend having a maintenance contract to prolong your transformer’s life and performance, starting from 12 months after installation and energisation.

If your Transformer hasn’t been inspected or undergone maintenance recently contact us and speak to our expert team.

Follow our team on LinkedIn for more updates.