Every month we share an industry word or acronym to translate some of the jargon from the electrical engineering world!

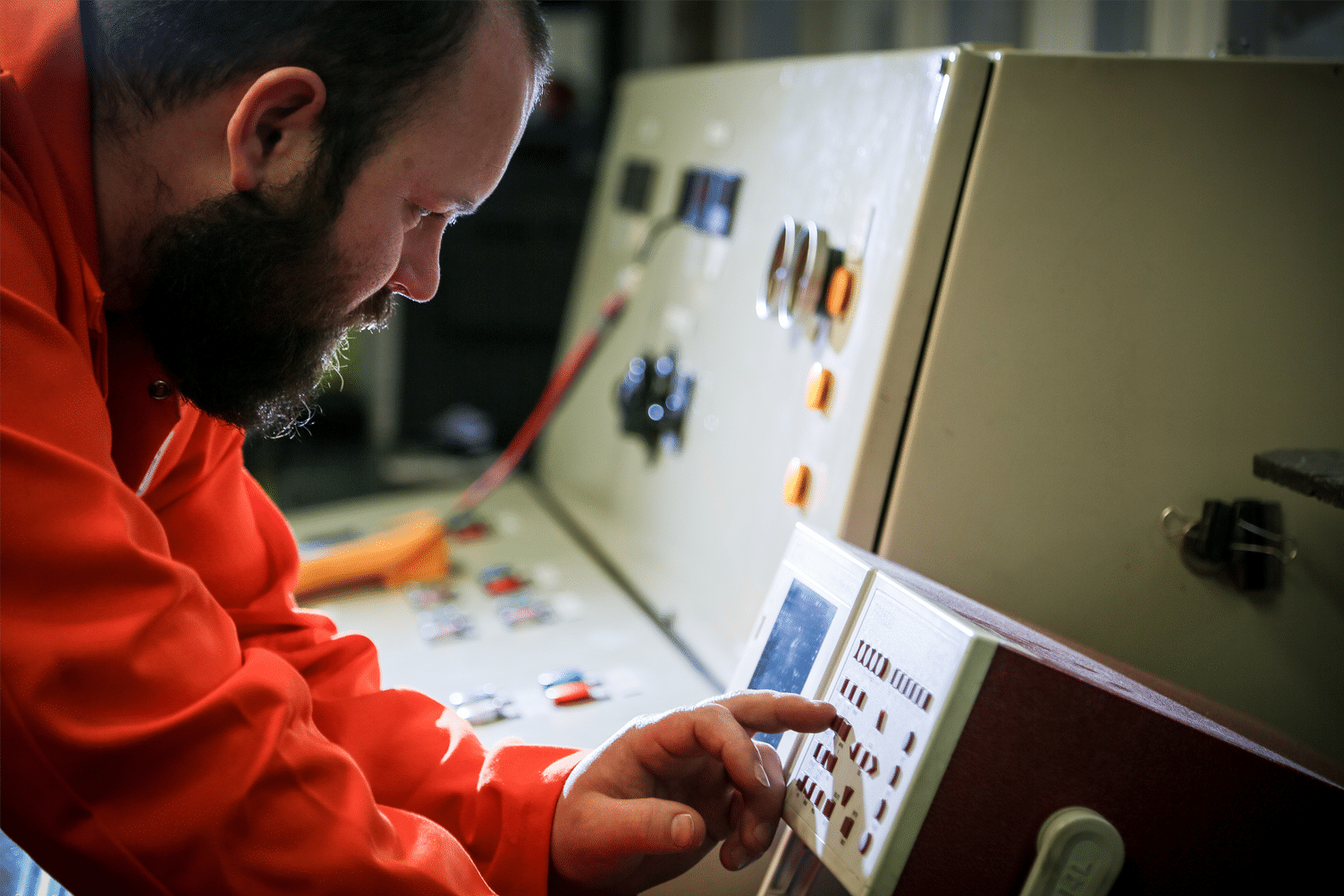

Factory Acceptance Testing (FAT) validates that your product is built and operating following design specifications and regulations. For transformers, it’s the process of testing to confirm that it meets all elements of the international standard BSEN60076-1 and the losses outlined by the EcoDesign regulation 548/2014.

The hassle of dealing with issues when equipment is operated the first time around can be a huge headache. Wouldn’t it be nice to get some reassurance before receiving your equipment? That’s what Factory Acceptance Tests, or FATs, are for.

The Factory Acceptance testing is not only beneficial for you as end-users and buyers but for Bowers as a supplier of the product. The FAT helps assure both parties that the new equipment complies with all contractual specifications. It also helps to address any functional issues before the equipment arrives at the installation site.

Should it be necessary, the FAT allows for the rectification of issues while the equipment is still in the factory and helps to keep the project on track and within budget.

As the names would suggest the difference between tests is the location in which the tests take place, one is in the factory where the product is supplied from and the second is the site in which the product is being installed.

SATs demonstrate that nothing has changed during transport and installation from the FAT. It also allows for site-specific set-up (for example, the tap changer).

Sounds like something that will benefit your project? Contact our team here.